CA Type (CNC Type)

COMPACT HARDWARE AND HIGH QUALITY HUMAN-MACHINE INTERFACT

- Industrial Class Computer(Pentium 266 CPU,32M RAM)

- 12.1"TFT LCD Display Panel

- Display Power and External Keyboard Inte-rface

- I/O Operator's Panel

- 4 Axes Closed-loop Motion control Card

- I/O Control Card

AUTOMATIC TOOL CHANGE, AUTO GUIDE CHANGE AND INTELLIGENT TOOL COMPENSATION

- Auto Tool Change control.

- Auto guide change.

- Auto compensation of replacement new electrodes while machining electrode is run out.

- Once the machining depth is reached, the electrode automatically returns to a fixed height above the workpiece.

- Variable deepness control of machining.

- Simulation and working path display.

- Many condition files - each file input has -100 discharge variables.

- 100 sets of drilling deepness

USER FRIENDLY AND COMPATIBLE

- Dialogue Programming

- G/M Code Programming

- Background Editing

- Special Modular Machining (Circle, Rectan-gle Patterns)

- Auto Edging. Centre of Two Points. Center of Circle Contains Electrode.

- Radius Compensation.

FLEXIBLE AND MAINTAINBLE

- Self-Diagnostic System Display

- Hardware Status Display

- Alarm History Management

- RS232 Trans Function

- Chinese/English Conversion

OCT-3525CA

Auto Guide Change(AGC)

Robot for ATC & AGC

AUTOMATIC TOOL CHANGE AUTO GUIDE CHANGE COMPONENTS

ATC & AGC Systerm

Auto Tool Change(ATC)

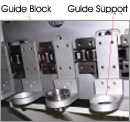

Guide chuck + Block

For CNC type

CNC EDM DRILL CONTROL FUNCTION:

| ITEM | FUNCTION |

|---|---|

| MCS | Maker setting of parameter |

| Program Edit | File 5000 Blocks Load, Insert, Delete, Copy, Save...... Program simulation Point coordinate input function from DXF file |

| Parameter Setting | Machining condition library Parameter list |

| Machining Method | Single hole machining Muitiple holes machining Special modular machining (Circle pattern, rectangle patten) Single block machining, auto machining |

| Manual Function | Positioning Auto Edge search Auto centering of two point Auto centering of two circle Jog function (Incremental, Continuous, Non-Protection) |

| Coordinate Display | Machine coordinate Work coordination Relative Coordinate Following error display |

| NC Function | 4 Axes closed loop control Servo feed control Auto electrode change Auto electrode compensation Pitch error compensation Interrupt point and start point restart Chinese/ English conversion Inch/ Metric conversion Emergency stop during machining (Auto detection for emergency condition) Selective program execution Program machining Start, Hold, Reset Subprogram call (Max: 8 layers) Modify parameter during machining Machining path display Work path display Machine time record and display Software limit protection Test run Auto error detection Axis rotation |

| G Code | G00 Fast Positioning G04 Hold Seconds G05 No Guard Fast Positioning G06 Check Point Set G30 Block Skip Cancel G31 Block Skip Active G38 Condition Table Change G53 Machine Coordinate Position G80 Edge Searching G81 Machine Origin Searching G82 Locate Groove Center G83 Locate Inner Hole G84 Locate Outer Center G85 Locate Circular Cylinder Center G90 Absolute Coordinate G91 Relative Coordinate G92 Work Coordinate Point Setting |

| M Code | M01 Program Hold M02 Program End M03 Spindle CW M04 Spindle CCW M05 Spindle Stop M06 Guide Change M08 Fluid Supply Start M09 Fluid Supply Stop M20 Electrode Change M36 Machine A Hole M98 Call Sub-Program M99 Sub-Program End |

| MODEL NO | OCT-3525CA | OCT-4535CA | OCT-5540CA |

|---|---|---|---|

| Table travel (X,Y axes) | 350 x 250 mm | 450 x 350 mm | 550 x 400 mm |

| Work table size | 600 x 300 mm | 600 x 300 mm | 800 x 450 mm |

| Z axis travel | 200 mm | 200 mm | 250 mm |

| W axis travel | 350 mm | 345 mm | 345 mm |

| The maximum height of workpiece | 330 mm | 330 mm | 420 mm |

| Max. workpiece weight | 250 kgs | 600 kgs | 1000 kgs |

| Power input | According to local voltage |

||

| Maximum average current | 32 Amps | 32 Amps | 32 Amps |

| Power capacity | 3.8 KVA | 3.8 KVA | 3.8 KVA |

| Electrode diameter | 0.1~3.0 mm | 0.1~3.0 mm | 0.1~3.0 mm |

| Machine net weight | 800 kgs | 1000 kgs | 1500 kgs |

| Depth / Width / Height | 1100 x 1200 x 2100 mm | 1600 x 1600 x 2300 mm | 2000 x 1800 x 2200 mm |

| *Due to continuous research and development, all specifications and design characteristics are subject to change without prior notice. *All the specifications are subject to change without prior notice. |

|||